|

parameters2:Capacity: 10m3/day--200m3/day

parameters3:Material: Steel

Installation underground Installation overground

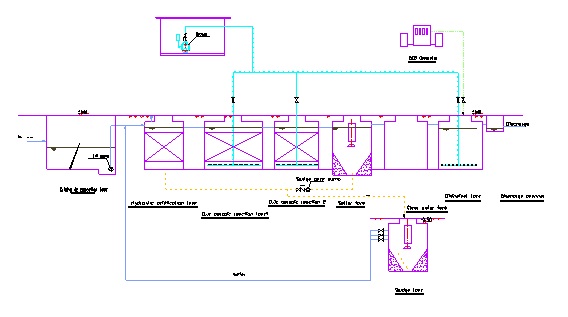

Flow diagram:

Treatment process :

The effluents flows into screen for big particles separating after collected by drain channel, then enters into adjusting tank for homogeneity and equant. A level controller is setted in the adjusting tank, who can deliver sign to CPU. The effluents were sent to A biological contact oxidation pond for acidification hydrolyzing and nitration-denitration in the order of reduce the concentration of organic matters and wiping and remove part ammonia nitrogen. After that enter into O biological contact oxidation pond for aerobiotic biochemical reaction. O biological pond is divided into two stages, and most organic contaminants are degraded by biological oxidation and adsorption. And now the effluents auto-flows to the second sediment pond for solid-liquid seperation. After that the upper clear liquid flows into disinfecting tank for bacterica remove by adding chlorinate chemicals. The disinfected clear liquid can be used for flower watering , toilet flushing, or discharge directly.

The sundries held back by the screen are collected by the truck and delivered to wasteyard regularly. The sludge in the second sedimentation tank , some reflux to A biological reaction tank and some are took off by the truck. The upper liquids of the sludge tank refluxs to adjusting tank for retreatment.

Package effluent treatment system main component:

|

NO. |

ITEM |

QTY. |

NO |

ITEM |

QTY. |

|

1 |

Screen |

1Pcs |

8 |

Sludge lifting equipment |

1Pcs |

|

2 |

Lift pump |

1Pcs |

9 |

Diffuser |

Pcs |

|

3 |

Level switch |

1Pcs |

10 |

Air blower |

1Pcs |

|

4 |

Containerized tank |

1Set |

11 |

Setter plate |

m2 |

|

5 |

Stuffing |

m2 |

12 |

ClO2 generator |

1Set |

|

6 |

Stuffing bracket |

1set |

13 |

Pipes&Valves |

1Set |

|

7 |

Manhole |

6Set |

14 |

Control box |

1Set |

Treatment capacity: